DOL Starter (Direct On Line Starter)

DOL Starter (Direct On Line Starter) Diagram & Working Principle

A DOL starter (or Direct On Line starter or across the line starter) is a method of starting of a 3 phase induction motor. In DOL Starter an induction motor is connected directly across its 3-phase supply, and the DOL starter applies the full line voltage to the motor terminals. Despite this direct connection, no harm is done to the motor. A DOL motor starter contains protection devices, and in some cases, condition monitoring. A wiring diagram of a DOL starter is shown below:

Since the DOL starter connects the motor directly to the main supply line, the motor draws a very high inrush current compared to the full load current of the motor (up to 5-8 times higher). The value of this large current decreases as the motor reaches its rated speed.

A direct online starter can only be used if the high inrush current of the motor does not cause an excessive voltage drop in the supply circuit. If a high voltage drop needs to be avoided, a star delta starter should be used instead. Direct on line starters are commonly used to start small motors, especially 3 phase squirrel cage induction motors.

As we know, the equation for armature current in the motor.The value of back emf (E) depends upon speed (N), i.e. E is directly proportional to N.

At starting, the value of E is zero. So starting current is very high. In a small rating motor, the rotor has more considerable axial length and small diameter. So it gets accelerated fastly. Hence, speed increases and thus the value of armature current decreases rapidly. Therefore, small rating motors smoothly run when it is connected directly to a 3-phase supply. If we connect a large motor directly across 3-phase line, it would not run smoothly and will be damaged, because it does not get accelerated as fast as a smaller motor since it has short axial length and larger diameter more massive rotor. However, for large rated motors, we can use an oil immersed DOL starter.

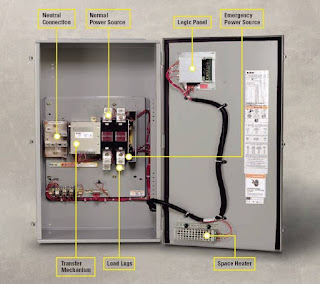

DOL Starter Wiring Diagram

The wiring diagram for a DOL stater is shown below. A direct online starter consits of two buttons, a GREEN button for starting and a RED for stopping purpose of the motor. The DOL starter comprises of an MCCB or circuit breaker, contactor and an overload relay for protection. These two buttons, i.e. Green and Red or start and stop buttons control the contacts.

To start the motor, we close the contact by pushing Green Button, and the full line voltage appears to the motor. A contactor can be of 3 poles or 4-poles. Below given contactor is of 4-pole type. It contains three NO (normally open) contacts that connect the motor to supply lines, and the fourth contact is “hold on contact” (auxiliary contact) which energizes the contactor coil after the start button is released. If any fault occurs, the auxiliary coil gets de-energized, and hence the starter disconnects the motor from supply mains.

3 Phase Motor Starter with Overload Protection

When a motor draws excessive current to meet the load requirements such that this load requirement goes beyond the rated limit, this is known as overload. Thermal overload protection is a type of security when the motor draws over current or excessive current and causes overheating of the equipment. Overload is also the type of over current. So overload relays are employed to limit the amount of current drawn.

But that does not mean that protects the short circuit. Fuse or MCB used in the system protects the over current. Overload protection opens a circuit at relatively low currents that are a little higher than the rating of the motor.Overload currents are likely to damage if they persist for a long time, i.e. it will not trip if a high value of current flows for a short period such as starting of the motor.We often provide overload protection via an overload relay. Overload relays may be solid-state devices with adjustable trip setting also called as the electronic relay or by interacting with related temperature sensors called as a thermal relay or if only operates for excess current flow then called as a magnetic relay. For most motors, the maximum rating of the overload protection device is 125% of the full load ampere rating.

DOL Starter Working Principle

The working principle of a DOL starter begins with the connection to the 3-phase main with the motor. The control circuit is connected to any two phases and energized from them only. When we press the start button, the current flows through contactor coil (magnetizing coil) and control circuit also. The current energises the contactor coil and leads to close the contacts, and hence 3-phase supply becomes available to the motor. The control circuit for a DOL Starter is shown below.

If we press the stop button, the current through the contact becomes discontinued, hence supply to the motor will not be available, and the similar thing will happen when the overload relay operates. Since the supply of motor breaks, the machine will come to rest. The contactor coil (Magnetizing Coil) gets supply even though we release start button because when we release start button, it will get supply from the primary contacts as illustrated in the diagram of the Direct Online Starter.

Advantages of DOL Starter

The advantages of a DOL starter include:

- Simple and most economical starter.

- More comfortable to design, operate and control.

- Provides nearly full starting torque at starting.

- Easy to understand and troubleshoot.

- DOL starter connects the supply to the delta winding of the motor.

Disadvantages of DOL Starter

The disadvantages of a DOL starter include:

- High starting current (5-8 times of full load current).

- DOL Starter causes a significant dip in voltage, hence suitable only for small motors.

- DOL Starter reduces the lifespan of the machine.

- Mechanically tough.

- Unnecessary high starting torque

DOL Starter Applications

The applications of DOL starters are primarily motors where a high inrush current does not cause excessive voltage drop in the supply circuit (or where this high voltage drop is acceptable).

Direct on line starters are commonly used to start small water pumps, conveyor belts, fans, and compressors. In the case of an asynchronous motor (such as the 3-phase squirrel-cage motor) the motor will draw a high starting current until it has run up to full speed.

Comments

Post a Comment